HPL Panel System

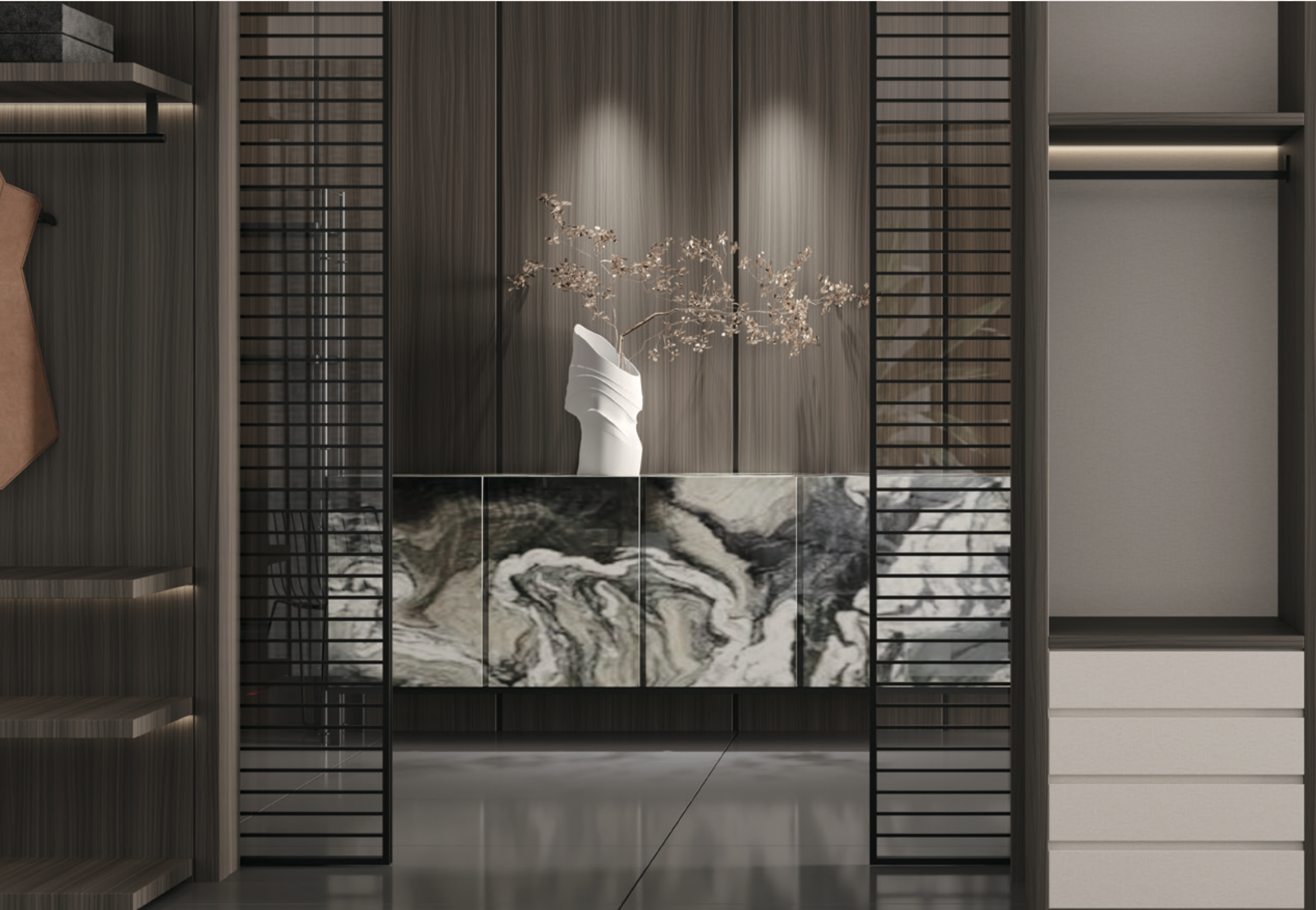

High-Pressure Laminate Panels for Walls & Surfaces

HPL Panels are high-performance decorative laminate systems engineered for interior wall and surface applications.

Manufactured through high-pressure consolidation of kraft paper and decorative layers, HPL offers durability, visual consistency, and controlled performance for commercial interiors.

Designed as a surface system rather than a finish, HPL panels support architectural detailing, modular coordination, and repeatable quality across projects.

System Overvie

HPL Panels are engineered as a complete wall and surface system, not loose decorative sheets.

Multi-layer high-pressure laminate construction

Suitable for interior wall and surface applications

Wide range of decorative finishes and textures

Consistent color and pattern control across production

Designed for system-based mounting and detailing

The system supports scalable use across large interior areas with predictable performance and visual consistency.

Typical Applications

Wall & Surface Applications

Commercial interior walls

Office and corporate environments

Hospitality interiors

Retail and showroom spaces

Education and institutional interiors

HPL is commonly used where durability, cleanability, and controlled aesthetics are required.

Typical Specifications

HPL Panels are supplied in architectural-grade formats suitable for interior wall and surface applications. Final specifications vary by project requirements, finish selection, and mounting system.

Typical panel thicknesses range from approximately ⅛–½ in (3–12 mm), depending on substrate and system configuration

Standard and large-format panel sizes available, including sheet-based and panelized systems

Multiple surface textures available, including matte, satin, gloss, and textured finishes

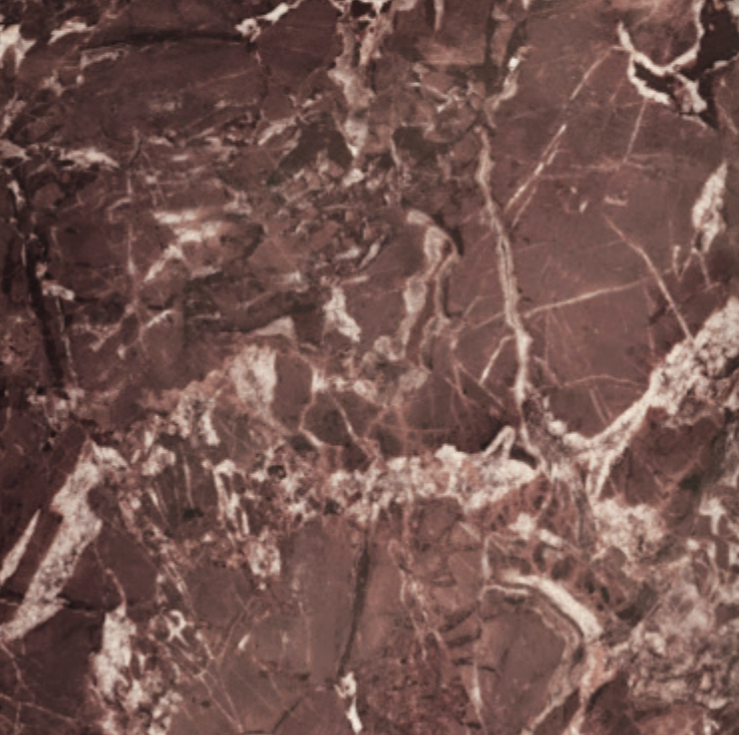

Extensive decorative range including solids, woods, stones, and abstract patterns

Designed for integration with aluminum framing, plywood backing, or direct substrate mounting

Detailed specifications, finish data, and submittal documentation are available upon request.

Design Flexibility

HPL offers one of the broadest decorative ranges among architectural surface systems.

Solid colors with controlled tonal consistency

Woodgrain and stone visuals with repeatable patterning

Abstract, textile, and graphic-inspired finishes

Multiple surface textures to control reflectivity and tactility

Consistent appearance across panels, corners, and junctions

This enables designers to achieve precise visual intent without the variability associated with natural materials.

System Performance

Durability & Wear Resistance

HPL surfaces are engineered for high resistance to abrasion, impact, and surface wear, supporting long-term use in commercial interiors.

Fire Performance

Fire-rated HPL grades are available to support use in regulated commercial and institutional environments when specified appropriately.

Hygiene & Maintenance

Non-porous laminate surfaces support easy cleaning and resistance to staining, making HPL suitable for high-use environments.

Installation Logic

HPL Panels are designed for system-based installation rather than site-fabricated finishes.

Compatible with aluminum subframe systems, plywood backing, or direct adhesive installation

Suitable for drywall, cement board, and prepared substrates

Panelized layouts support clean joints, reveals, and access detailing

Installation methods can be adapted for new construction or retrofit projects

This system approach enables predictable installation quality and repeatable detailing.

Certification & Documentation

Fire performance data, surface testing, and environmental documentation are available upon request.

Specification support and documentation are provided for commercial and institutional projects.

How we work

Single point of coordination from specification through delivery.

Carve Materials supports HPL Panel systems as part of an integrated wall and surface solution. Our process is designed to assist architects, developers, and contractors with system selection, detailing, and coordinated delivery for real project conditions.

1. Project Brief

Application scope, finish intent, performance requirements, and system constraints are confirmed.

2. System Selection

Panel formats, thickness ranges, decorative finishes, and mounting systems are coordinated to align with design intent and project conditions.

3. Specification

Finish data, system details, and relevant documentation are provided to support specification and coordination.

4. Production & Delivery

Approved systems move into coordinated production and are delivered in alignment with project sequencing and site readiness.