Wall & Surfaces

Architectural wall systems designed for performance, durability, and visual clarity.

Carve Materials curates wall and surface systems for commercial interiors where acoustic control, durability, and architectural intent must coexist.

Our systems are designed to install efficiently, perform reliably, and integrate seamlessly into real projects—from offices and hospitality to education and institutional environments.

We organize our wall offerings into two clear system families: Acoustic Wall Systems and Durable / Architectural Surfaces.

For off-the-shelf acoustic panel products, please visit our sister brand carvecreation.com

Acoustic Wall Systems

Wall-based acoustic solutions for spaces where sound control and spatial experience are equally important. These systems are designed for eye-level use, clean detailing, and modular installation.

-

Design-led acoustic panels manufactured from high-density recycled PET fibers.

PET felt panels combine effective sound absorption with a clean, contemporary appearance. Their through-body construction allows for precise cutting, crisp edges, and modular layouts—making them ideal for feature walls, collaboration areas, and client-facing interiors.

Key characteristics

Acoustic performance for mid–high frequency control

Lightweight, modular, and fast to install

Clean edges suitable for exposed wall applications

Sustainable material profile (recycled content)

Typical applications

Offices, meeting rooms, coworking spaces, education, collaboration zones -

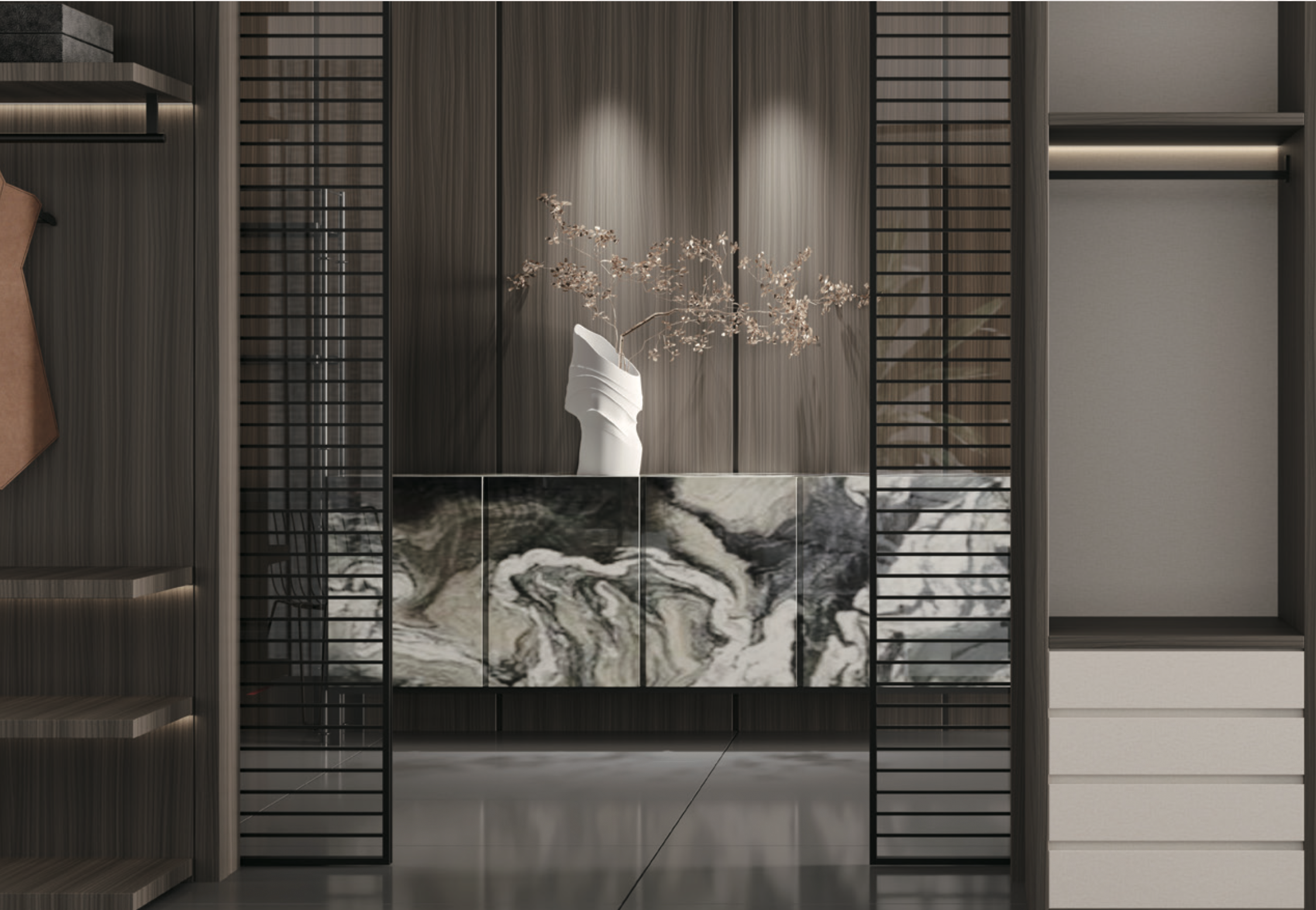

Architectural slat systems with integrated acoustic backing.

Engineered wood slat panels introduce warmth, rhythm, and material depth while delivering reliable acoustic performance. Designed as complete wall systems, they balance visual presence with technical function and are widely accepted in commercial and hospitality interiors.

Key characteristics

Engineered wood slats with concealed acoustic backing

Clean, repeatable system detailing

Warm architectural expression with sound control

Modular installation for consistent results

Typical applications

Lobbies, conference rooms, hospitality interiors, executive spaces. -

Classic acoustic wall systems with controlled fabric finishes.

Fabric-wrapped panels provide dependable acoustic performance and are commonly specified where a softer visual language is desired. When tightly curated, they integrate well into professional interiors without reading as temporary or decorative.

Key characteristics

Proven acoustic performance

Wide fabric and color options (curated palette recommended)

Modular panel formats

Suitable for wall-mounted acoustic treatment

Typical applications

Conference rooms, education, corporate offices, training spaces

Durable / Architecture Surfaces

Non-acoustic wall systems designed for impact resistance, longevity, and architectural finish. These materials perform in high-traffic environments while maintaining visual control.

-

High-pressure laminate systems for commercial wall protection and finish.

HPL wall panels offer excellent durability and surface consistency, making them a reliable solution for corridors, shared spaces, and areas requiring frequent cleaning and long service life.

Key characteristics

High abrasion and impact resistance

Consistent surface finish and color stability

Suitable for high-traffic commercial environments

Systemized installation options

Typical applications

Corridors, offices, education, healthcare, hospitality back-of-house -

Solid-core laminate panels for enhanced durability and rigidity.

Compact laminate panels extend beyond standard HPL by offering a thicker, self-supporting construction. They read more architectural while maintaining exceptional durability, making them suitable for demanding commercial environments.

Key characteristics

Solid-core construction

High moisture and impact resistance

Clean edge detailing

Suitable for wall cladding and partitions

Typical applications

Education, healthcare, restrooms, circulation spaces, institutional interiors -

Premium solid-surface wall panels with refined architectural presence.

Mineral core panels deliver a dense, stone-like appearance with precise edges and controlled surface quality. They are used where a more refined, premium finish is required without the complexity of natural stone installation.

Key characteristics

Solid, high-density core

Clean edges and refined finish

Durable and low maintenance

Elevated architectural appearance

Typical applications

Lobbies, feature walls, hospitality interiors, high-end commercial spaces

Certification & Performance Standards

Carve Materials wall and surface systems are designed to meet common commercial performance, safety, and wellness requirements. Certifications and test reports vary by system and configuration and are available upon request.

Acoustic Performance

NRC testing in accordance with ASTM C423 / ISO 354 (system dependent)

Fire Performance

ASTM E84 / UL 723 (Class A assemblies where applicable)

EN 13501 classifications available for select systems

Indoor Air Quality

UL GREENGUARD / GREENGUARD Gold compliant systems

Low-VOC material options available

Material Performance

Impact and abrasion resistance for HPL and compact laminate systems

Moisture-resistant constructions for demanding environments

Project-specific certifications, test reports, and submittals can be provided during specification and coordination.

How we Work

Carve Materials delivers wall systems, not raw materials.

Each offering is developed with system logic, detailing considerations, and project-based coordination to ensure predictable results on site.

Carve Materials works with architects, developers, and contractors to deliver wall and surface systems suited for real commercial projects. Our process is designed to support specification, coordination, and efficient installation.

1. Project Brief

We review your project scope, performance requirements, and design intent. This may include drawings, finish schedules, or conceptual direction.

2. System Selection

Based on your requirements, we recommend suitable wall or surface systems, materials, and configurations aligned with performance, budget, and installation constraints.

3. Specification

We support specification with system details, material options, and relevant performance information. Coordination with consultants, contractors, or fabricators is provided as needed.

4. Production & Delivery

Once systems are confirmed, materials are produced and delivered according to project timelines. Lead times and logistics are coordinated to align with site schedules.