Pet Felt Panel

Recycled PET Acoustic Panels for Walls & Ceilings

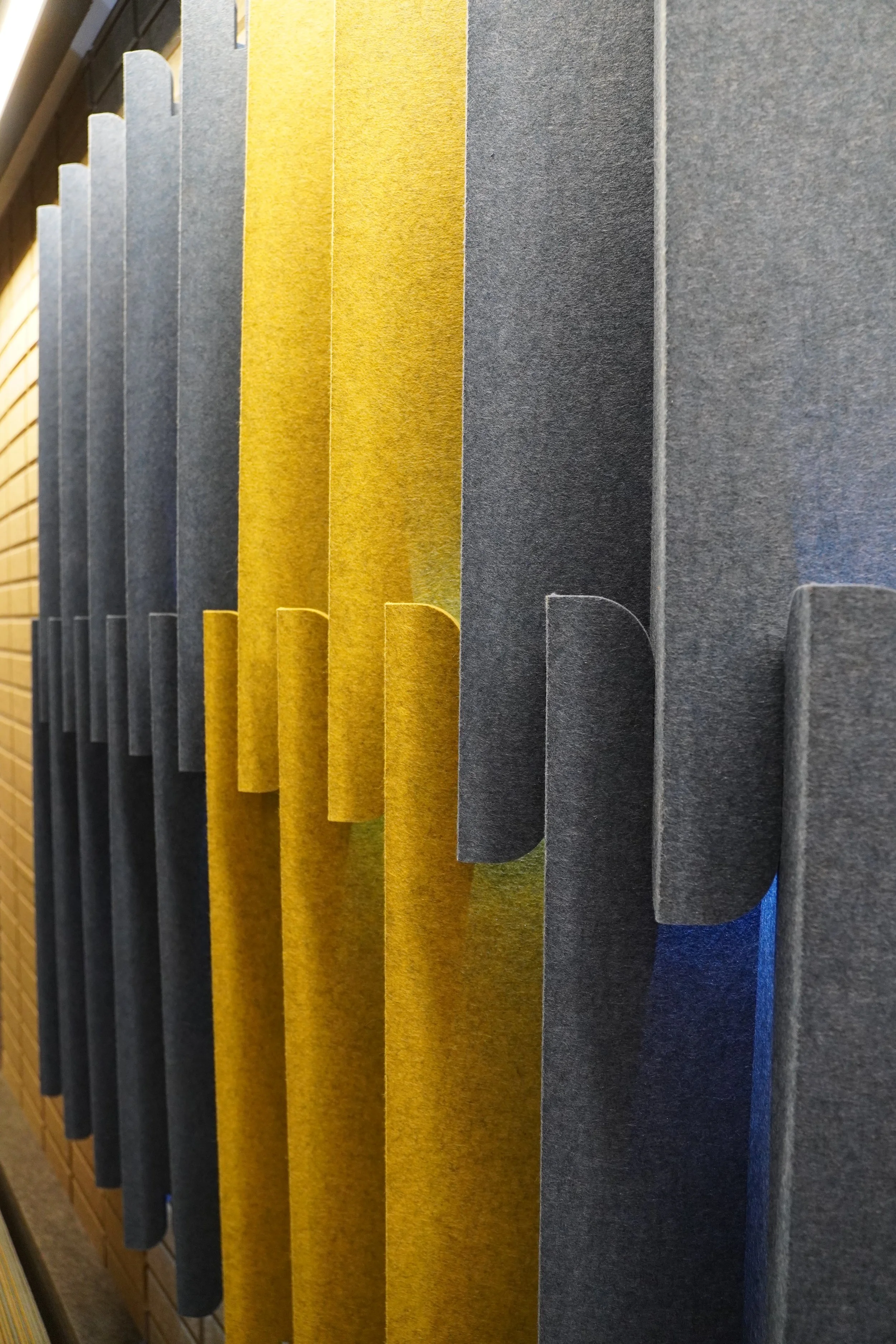

PET Felt Panels are lightweight acoustic surface systems manufactured from recycled polyester fibers.

Designed for interior wall and ceiling applications, they provide sound absorption, visual softness, and design flexibility for modern commercial interiors.

Engineered as a panelized system rather than a soft finish, PET Felt Panels support architectural detailing, modular coordination, and repeatable performance across projects.

System Overview

PET Felt Panels are designed as a complete acoustic wall and ceiling system, not loose decorative elements.

Recycled PET fiber construction

Suitable for interior wall and ceiling applications

Lightweight panels with controlled acoustic performance

Consistent color and density across production

Designed for modular layouts and system-based installation

The system enables acoustic treatment to be integrated cleanly into architectural surfaces without excessive structural load or complex installation.

Typical Applications

Wall & Ceiling Applications

Office interiors and meeting rooms

Open workspaces and collaboration areas

Hospitality interiors

Education and institutional spaces

Sales galleries and public interiors

PET Felt Panels are commonly used where acoustic comfort and visual softness are required.

Typical Specifications

PET Felt Panels are supplied in architectural-grade formats suitable for wall and ceiling applications. Final specifications vary by project requirements, panel design, and installation method.

Typical panel thicknesses range from approximately ⅜–¾ in (9–20 mm)

Standard panel sizes and modular formats available, with cut-to-size options

Flat panels, grooved panels, and profiled surface designs available

Solid color ranges with consistent tone and fiber distribution

Lightweight system suitable for retrofit and ceiling applications

Detailed specifications, acoustic data, and submittal documentation are available upon request.

Design Flexibility

PET Felt Panels offer high design adaptability through cutting, profiling, and color control.

Solid and neutral color palettes

CNC-cut patterns, grooves, and relief designs

Panelized layouts with controlled jointing

Geometric, linear, or custom surface expressions

Compatibility with integrated lighting and feature walls

Because the material is homogenous through its thickness, cut edges remain clean and visually consistent.

System Performance

Acoustic Performance

PET Felt Panels provide sound absorption suitable for reducing reverberation and improving speech clarity in interior environments when applied as part of a coordinated acoustic strategy.

Dimensional Stability

The fiber-based structure maintains shape and density under normal interior temperature and humidity conditions.

Material Logic

Manufactured from recycled polyester fibers, PET Felt Panels support material reuse and durability-focused sustainability strategies.

Installation Logic

PET Felt Panels are designed for fast, system-based installation.

Compatible with adhesive mounting, mechanical fixing, or track systems

Suitable for drywall, gypsum board, plywood, and prepared substrates

Lightweight panels reduce installation labor and structural requirements

Applicable to both wall and ceiling installations

This approach supports clean detailing and efficient on-site execution.

Certification & Documentation

Acoustic test data, fire performance documentation, and environmental information are available upon request.

Specification support and documentation are provided for commercial and institutional projects.

How we work

Single point of coordination from specification through delivery.

Carve Materials supports Pet Felt Panel systems as part of an integrated wall and surface solution. Our process is designed to assist architects, developers, and contractors with system selection, detailing, and coordinated delivery for real project conditions.

1. Project Brief

Application scope, acoustic intent, panel type, and design direction are confirmed.

2. System Selection

Panel thickness, format, surface pattern, and color selection are coordinated based on design and acoustic requirements.

3. Specification

System details, acoustic data, and relevant documentation are provided to support specification and coordination.

4. Production & Delivery

Approved systems move into coordinated production and are delivered in alignment with project sequencing and site readiness.