Mineral Core Panels

Mineral-Based Architectural Panels for Walls & Floors

Mineral Core Panels are high-performance architectural surface systems built around a quartz-rich, mineral-based core.

Engineered for both wall and flooring applications, they deliver the refined appearance of stone surfaces while significantly reducing weight, installation complexity, and system constraints.

Designed for modern interiors that demand durability, consistency, and design control, Mineral Core Panels provide a stable, non-plastic alternative to traditional tile, stone, and plastic-based panel systems.

Designed for Wall & Flooring Applications

Unlike many lightweight panels that are limited to vertical use, Mineral Core Panels are engineered for:

Wall applications (vertical)

Flooring applications (horizontal)

This enables designers and developers to maintain material continuity between walls and floors while preserving structural efficiency, dimensional stability, and long-term performance.

System Characteristics

Quartz-rich, mineral-based core

Suitable for wall and floor applications

Significantly lighter than stone or ceramic systems

High dimensional stability

High design consistency across batches

Higher fire performance than plastic-based panels

Designed for modular and system-based installation

Typical Specifications

Mineral Core Panels are supplied in architectural-grade formats suitable for both wall and floor applications. Final specifications vary by project requirements, finish selection, and installation system.

Typical thicknesses range from approximately ¼–⅜ in (6–10 mm), depending on wall or floor application

Large-format panels available up to approximately 4 × 10 ft (1200 × 3000 mm), with modular and cut-to-size options

Multiple edge profiles available, including square, micro-bevel, and interlocking configurations

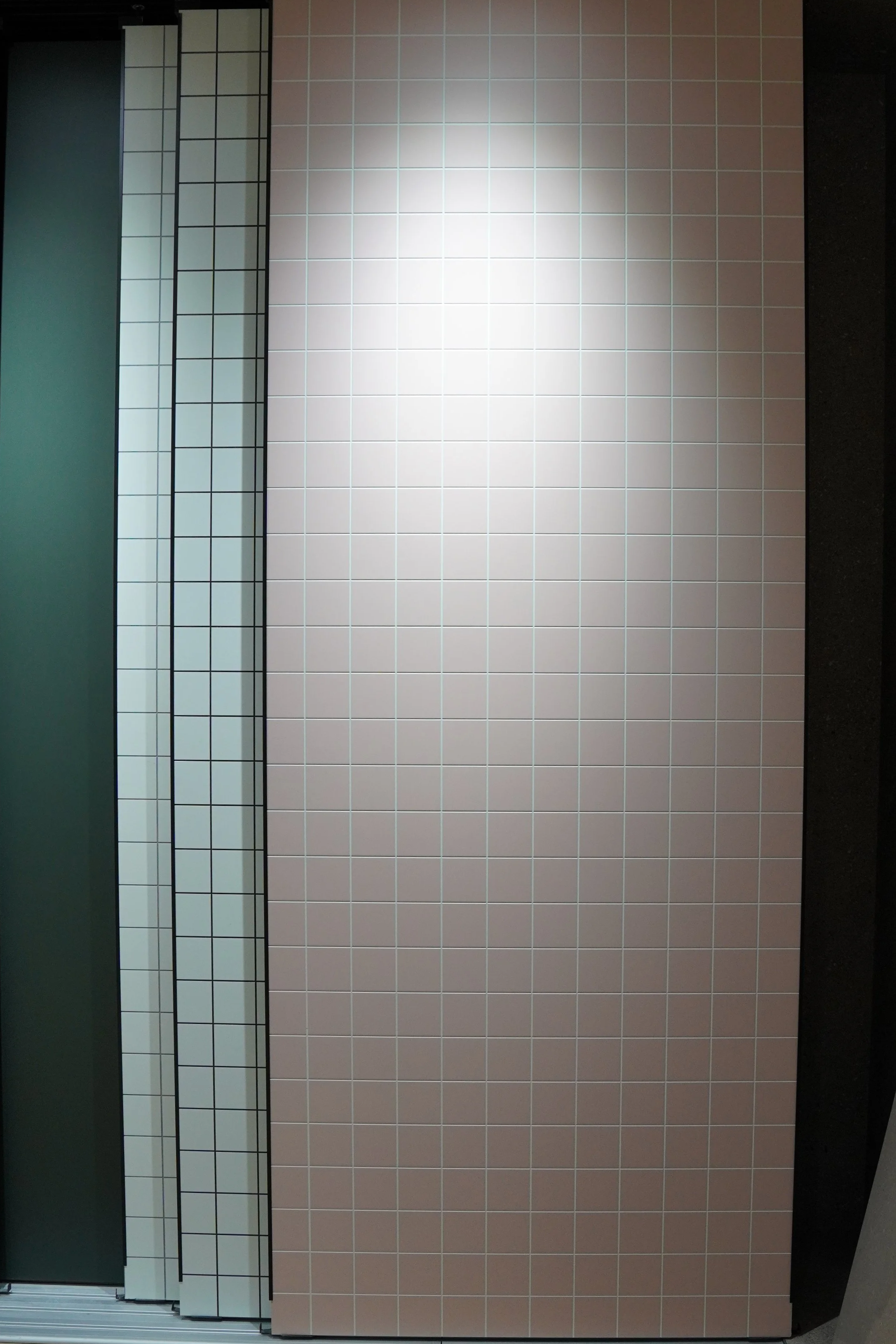

Matte, skin-touch, and gloss surface finishes available

Significantly lighter system weight compared to ceramic tile and stone surfaces

Detailed specifications, test reports, and submittal documentation are available upon request.

Design Flexibility

Mineral Core Panels are not limited to predefined visuals.

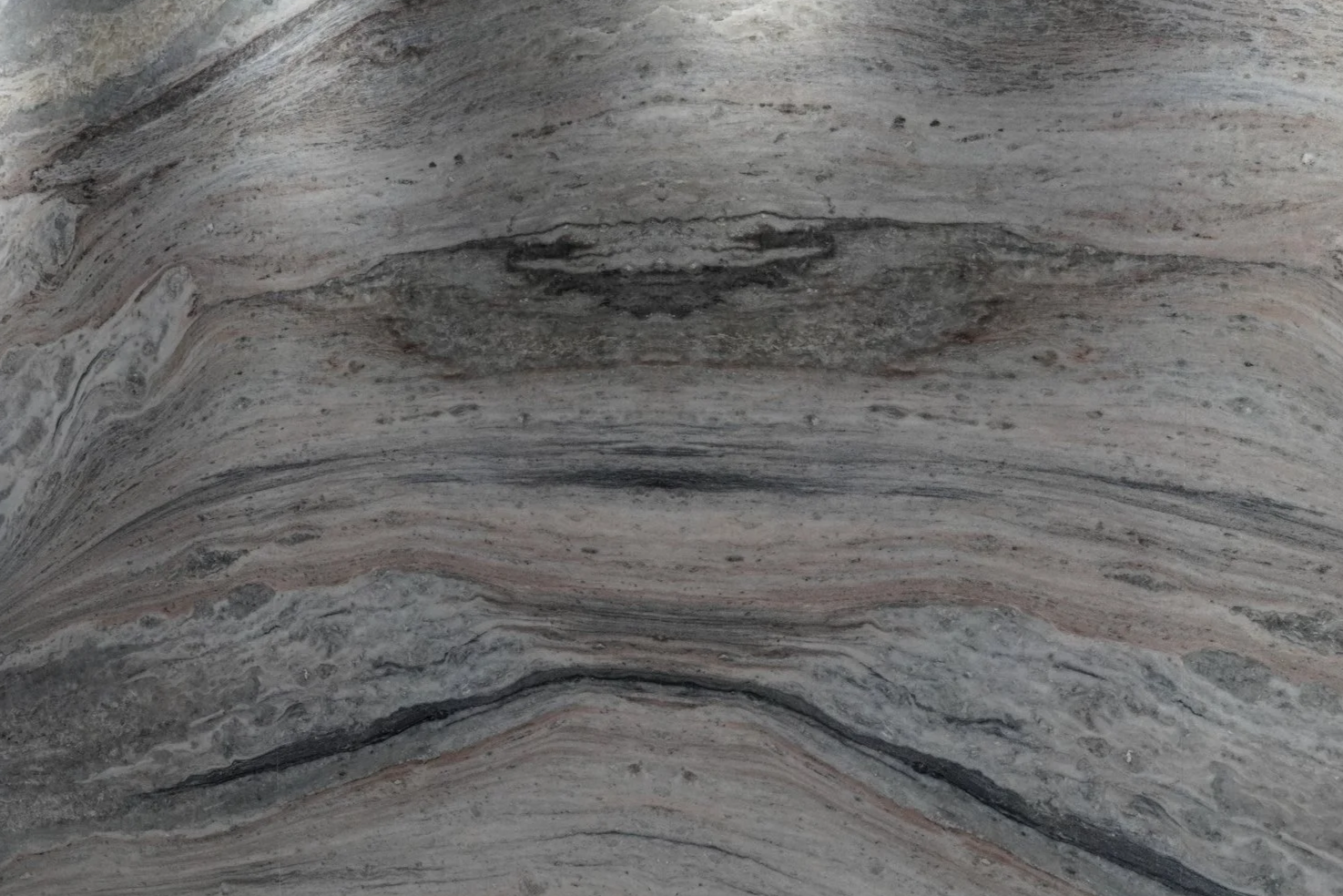

Because the surface layer is engineered rather than quarried, patterns and textures are not constrained by natural geology or material inconsistency.

This allows designers to specify:

Custom colors and calibrated tones

Continuous large-scale graphics

Controlled repeat or non-repeat patterns

Abstract, stone-inspired, or brand-driven surfaces

Coordinated wall-to-floor visual systems

Design intent can be carried across large areas while maintaining consistency and production accuracy.

Why Mineral Core Panels

Stone-Like Appearance, Reduced System Weight

Mineral Core Panels deliver the visual solidity expected from stone surfaces without the structural penalties typically associated with tile or slab systems.

Reduced structural load

Easier handling and installation

Lower transportation and labor costs

Ideal for renovation, retrofit, and multi-story projects

More Stable Than Plastic-Based Systems

Unlike SPC, WPC, or other plastic-dominant panels, Mineral Core Panels rely on an inorganic mineral core structure.

Minimal thermal expansion and contraction

Improved dimensional stability over time

Reduced risk of warping or deformation

Suitable for long-term architectural use

Higher Fire Performance

Thanks to their inorganic mineral composition, Mineral Core Panels achieve higher fire performance than plastic-based panel systems.

Improved fire resistance potential

Reduced flame spread characteristics

Better alignment with commercial and public building requirements

Applicable to both wall and floor installations

Clear Environmental Logic

Mineral Core Panels are built around mineral content rather than plastic binders.

Inorganic, mineral-dominant core

No reliance on PVC-based structures

Aligned with long-term durability and sustainability goals

Suitable for projects emphasizing material transparency and indoor safety

Typical Applications

-

Commercial flooring

Office interiors

Hotel public areas

Showrooms and high-traffic spaces

-

Commercial interior walls

Office and corporate spaces

Hotels and hospitality environments

Sales galleries and showrooms

Installation Logic

Mineral Core Panels are designed for system-based installation, supporting both traditional and prefabricated construction workflows.

Compatible with architectural adhesives or dry-install assemblies

Suitable for prepared substrates including drywall, cement board, and existing finishes

Flexible joint strategies, including tight seams or expressed reveals

Applicable to wet and dry interior environments with proper detailing

This approach enables fast installation, predictable outcomes, and controlled detailing across projects.

Certification & Documentation

Fire, VOC, and environmental test reports are available upon request.

Our team supports specification review and documentation for commercial and institutional projects.

How we work

Single point of coordination from specification through delivery.

Carve Materials supports Mineral Core Panel systems as part of an integrated wall and surface solution. Our process is designed to assist architects, developers, and contractors with system selection, detailing, and coordinated delivery for real project conditions.

1. Project Brief

Application type, performance requirements, panel format, and finish intent are reviewed at the outset. This may include drawings, finish schedules, or conceptual design direction.

2. System Selection

Panel sizes, thickness ranges, edge profiles, and surface finishes are coordinated to align with design intent, installation conditions, and project constraints.

3. Specification

We support specification development with system details, material options, and relevant performance documentation. Coordination with consultants, contractors, or fabricators is provided as needed.

4. Production & Delivery

Once specifications are confirmed, panels move into coordinated production and are delivered in alignment with project sequencing, lead times, and site readiness.